How to Choose Household Kitchen Knives (Chef’s Knives)?

I. Rockwell Hardness and Forging Process

II. Common Issues with Kitchen Knives

III. Steel for Kitchen Knives

IV. Essential Knife for Home Kitchen – Chef Knife

V. Essential Knife for Home Kitchen – Bread Knife

VI. Essential Knife for Home Kitchen – Santoku Knife

VII. Other Auxiliary Knives – Petty Knife

Ever since humans learned to use tools, the “knife” – as the most important and fundamental tool for humans to confront nature, has always occupied an irreplaceable position in human development history. From stone knives in the Stone Age, to bronze knives, iron knives and later stainless steel and ceramic knives, knives have formed an extremely large family. As the most widely used type of knives – “kitchen knives”, they are a must-have for every household.

I. Rockwell Hardness and Forging Process

■ Rockwell Hardness HRC is mainly used to measure the hardness of metals. The Rockwell hardness of kitchen knives is mostly between 52-64.

Different steel materials have different Rockwell hardness levels.

The roles of different components in steel materials:

Carbon (C): The higher the carbon content, the harder the steel becomes, but also more brittle and prone to rusting.

Chromium (Cr): Provides corrosion resistance. The higher the chromium content, the more resistant to rusting. Generally, if the chromium content exceeds 13%, it can be classified as “stainless steel”.

Molybdenum (Mo): Increases the steel’s resistance to corrosion.

Vanadium (V): Increases the hardness of the steel.

■ Forging Process

Full Tang (本烧 or 覆土烧刃 in Japanese):

This is an advanced forging method where the entire knife is made from a single piece of high-carbon steel. Clay is coated over the blade edge before forging to create an extremely hard, sharp cutting edge. This method requires very high skill and has a high failure rate, making full tang knives quite expensive.

San-Mai (三枚合 in Japanese):

The core of the blade is made from a hard, high-carbon steel. This is sandwiched between two outer layers of softer, tougher steel. This combines the hard cutting edge with a strong, flexible knife body.

Honyaki (本焼 in Japanese):

A thin outer jacket of hard, high-carbon steel wraps around a softer iron core. So it’s essentially the reverse of san-mai with the hard steel on the outside.

Honyaki (包钢 or 甲伏锻 in Japanese):

Similar to honyaki but using a high-carbon steel plate that is folded over and forge-welded around a softer iron core.

II. Common Issues with Kitchen Knives

How can I simply tell if a knife is of good or bad quality?

Celebrity chef Wang Gang’s method: Hit the knife blade with another knife, the longer the trailing sound/ringing lasts, the better the quality of the knife.

The idea is that a higher quality, well-forged knife blade will produce a longer ringing sound when struck, compared to a lower quality blade. Listening to the duration of the ringing tone provides a simple way to gauge the overall quality and construction of the knife without specialized equipment.

How do you tell if the blade is sharp with your eyes?

View the blade edge straight on. If there are silver-white spots on the blade edge, those are the dull portions. A well-sharpened knife blade, when viewed straight on, will look like an extremely thin black line and will not have any white spots.

Common issues with kitchen knives:

Dullness: One of the most common issues is a dull blade. Over time, knives can lose their sharpness due to regular use and improper maintenance. Dull knives can make cutting and slicing difficult and increase the risk of accidents.

Rust and corrosion: If knives are not properly dried after use or stored in a humid environment, they can develop rust and corrosion. This can affect the blade’s performance and even contaminate food.

Poor balance: A poorly balanced knife can make it challenging to control and maneuver. It can affect your cutting precision and make the knife feel uncomfortable to use.

Chipping or breaking: Knives can chip or break if they are mishandled or used on hard surfaces like bones or frozen foods. This can compromise their functionality and pose a safety risk.

Handle issues: The handle of a knife may become loose, cracked, or uncomfortable to grip over time. This can affect your control and make it difficult to use the knife effectively.

Inadequate maintenance: Lack of proper care and maintenance can lead to various issues with kitchen knives. This includes improper cleaning, using the wrong cutting board (such as glass or stone), or storing knives in a cluttered or unsafe manner.

III. Steel for Kitchen Knives

(1) X Chromium Steel: The number indicates the carbon content in thousandths, so 9Cr steel contains 0.9% carbon. The higher the carbon content, the greater the hardness.

- Below 5Cr steel: Used for low-end knives with relatively low hardness, limited sharpness, wear resistance and lifespan.

- 5Cr steel: Used for mid-range knives.

- 7Cr, 8Cr, 9Cr steels: Used for high-end knives with high hardness and sharpness. But due to excessive hardness, the blade is prone to chipping. To solve this, a clad/san-mai construction is often used with a high carbon/chromium core and tougher lower carbon steel on the sides.

(2) X50CrMoV15: The mainstream German steel for kitchen knives, with good corrosion resistance and toughness. 50 indicates 0.5% carbon content, with added molybdenum (Mo) and vanadium (V). Roughly equivalent to Chinese-produced 5Cr steel. Another common German steel grade is 1.4116 molybdenum vanadium steel, equivalent to X45CrMoV15.

Note: German ice-hardening is a renowned heat treatment where the steel is quenched at -200°C to improve physical properties.

(3) VG-10: A high-end stainless steel produced by Takefu Special Steel in Japan. VG-10 (V-Gold 10) is their highest grade, also called “V-Kin 10”. With a Rockwell hardness up to 60HRC, it is used by brands like Shun and Sakai Takayuki knives. There is also an upgraded version called VG-MAX.

(4) Aogami Steel: Traditional Japanese steel by Hitachi Metals in Aogami city. Classified into White, Blue, Silver and Yellow paper series.

(5) Damascus Steel: Used in the famed Damascus swords, originally from India’s wootz steel ingots.

(6) Powder Metallurgy Steel: Made by spraying molten steel into nitrogen gas to rapidly solidify into powder, then compressed at high temperature/pressure. Known for high hardness.

(7) Zirconia Ceramic: Made from zirconia and alumina powders under extreme pressure and heat. Hard but brittle.

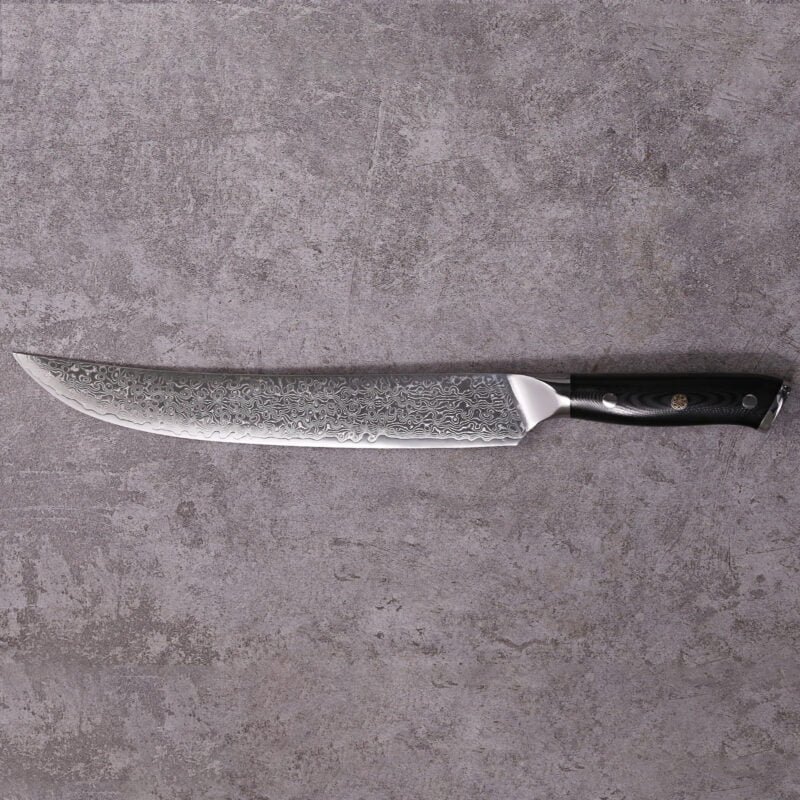

IV. Essential Knife for Home Kitchen – Chef Knife

The chef’s knife is arguably the most versatile and important knife in any home kitchen. It is an all-purpose workhorse used for most cutting tasks like slicing, dicing, mincing, and chopping vegetables, herbs, meats and more.

Shun is a highly esteemed Japanese knife brand known for their masterfully crafted cutlery. Their Classics series showcases traditional Japanese knife-making with blades formed of layered Damascus steel produced using a samurai sword-making technique dating back over 700 years. The Damascus layers support a razor-sharp core while adding distinctive beauty. Classics handles marry Japanese wood with a D-shaped profile for comfortable grip.

Incredibly sharp, this knife excels at precision slicing and dicing soft ingredients like vegetables and boneless meats. However, its razor-like edge is too brittle for chopping bones or extremely hard foods, which can easily chip the blade. While superb for delicate kitchen tasks, care must be taken to avoid using this knife on overly rigid items, as its hardness comes at the cost of reduced toughness against abuse. A thicker, tougher blade is better suited for heavy-duty cutting.

For heavy-duty chopping jobs like bones and thick meats, a meat cleaver is the right knife.

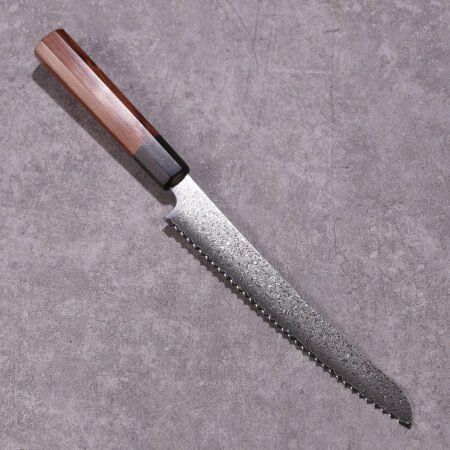

V. Essential Knife for Home Kitchen – Bread Knife

A serrated bread knife with a long, gently curved blade effortlessly slices through crusty loaves without crushing them.

The Dalstrong Shogun Series ELITE 10.25″ Bread Knife features ultra-sharp serrated edges meticulously hand-crafted from premium Japanese high-carbon AUS-10V steel for precise slicing of crusty bread loaves.

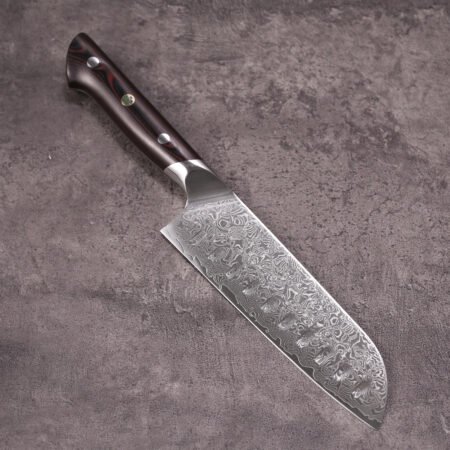

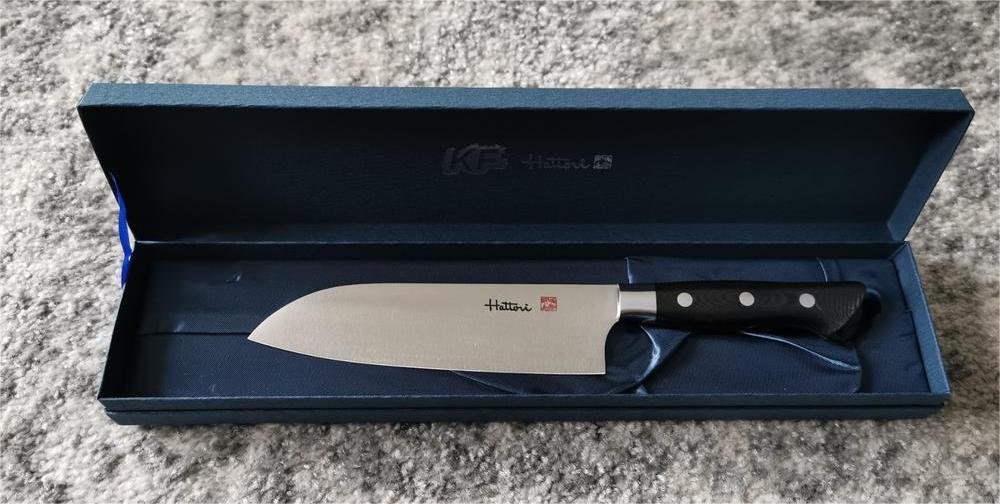

VI. Essential Knife for Home Kitchen – Santoku Knife

The santoku is a beautiful, Asian-inspired all-purpose kitchen knife that has become a modern favorite. Slightly shorter than a traditional chef’s knife, it combines versatility with agility. The gently curved blade profile allows for rocking cuts, while the compact length ensures easy maneuverability.

This 7-inch Santoku fits like an extension of your hand, feeling lightweight yet providing control. It excels at the push-cutting motion that many cooks prefer over the rocking action of larger knives. With its prowess at basic slicing, dicing, and mincing tasks, the Santoku demonstrates why it’s often lauded as a top-performing kitchen workhorse.

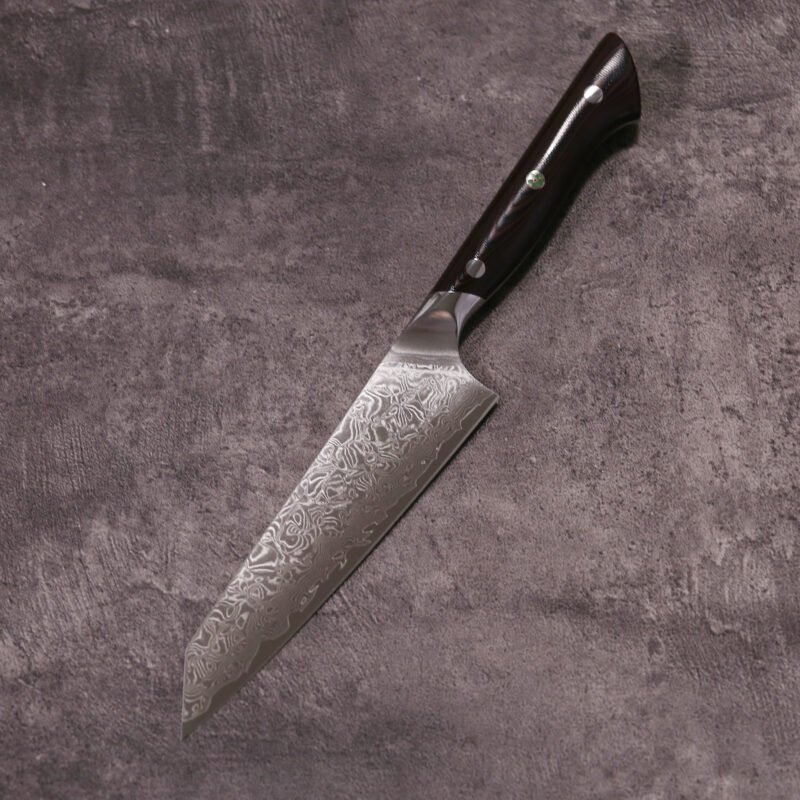

VII. Other Auxiliary Knives – Petty Knife

A petty knife, a small utility blade around 4-6 inches, is a handy auxiliary knife for trimming, deveining, mincing herbs and garnishes.

We support custom engraving on petty knives, allowing you to personalize these handy utility blades with names, initials, or special messages.