What Makes a Great Kitchen Knife?

Table of Contents

When we want to buy a good chef’s knife, there are many brands available in the market and there are many series subdivided within each brand. Each series uses different designs, steel, and handle shapes. At this point, many of us will learn a lot of buying tips on Google, tutorials on YouTube, etc., but all this work will make us feel tired and stressed.

We’ve been specialising in kitchen knives for over 15 years. Today we’re going to give you a little bit of knowledge about kitchen knives in terms of technical design, and materials, and some advice on how to pick a good knife.

The Steel

Carbon Steel

- 1095 Carbon Steel: Hardness of 58-62 HRC. Good edge retention, easy to sharpen, but susceptible to rust and staining.

- 52100 Bearing Steel: Hardness of 60-64 HRC. Excellent edge retention and wear resistance, but more difficult to sharpen.

Stainless Steel

- AUS-10: Hardness of 58-62 HRC. High-quality Japanese stainless steel with good edge retention and corrosion resistance.

- AUS-8: Hardness of 58-60 HRC. Affordable Japanese stainless steel with decent edge retention and corrosion resistance.

- X50CrMoV15: Hardness of 56-58 HRC. German stainless steel with good toughness and corrosion resistance.

High-Carbon Stainless Steel

- CPM S30V: Hardness of 58-62 HRC. Premium American stainless steel with excellent edge retention, wear resistance, and corrosion resistance.

Developed by Crucible Industries (now part of Crucible Materials Corporation)

Composition: 1.45% carbon, 14% chromium, 4% vanadium, 2% molybdenum

Hardness range: 58-62 HRC

Excellent wear resistance and edge retention due to high vanadium content

Very good corrosion resistance from chromium content

Tough and impact-resistant

Can be difficult to sharpen compared to simpler carbon steel

Used in high-end kitchen knives, outdoor/tactical knives, hunting knives

- CPM S35VN: Hardness of 59-61 HRC. High-end American stainless steel with superior edge retention, wear resistance, and toughness.

Also developed by Crucible Industries

Composition: 1.45% carbon, 14% chromium, 3% vanadium, 2.5% molybdenum, 1% niobium

Hardness range: 59-61 HRC

Superior wear resistance and edge retention over S30V due to niobium addition

Excellent corrosion resistance

High toughness and resistance to chipping/breaking

Very fine carbide structure from powder metallurgy process

Harder to sharpen than S30V

Used in premium kitchen knives, high-end folding knives, razors

Both S30V and S35VN are considered premium “super-clean” stainless steels made via the powder metallurgy process. This process minimizes impurities and allows for very fine and uniform carbide distributions.

Their high carbon, chromium, vanadium and molybdenum contents give them exceptional edge holding ability, wear resistance and corrosion resistance compared to standard stainless steels.

However, their high alloy compositions also make them more difficult to sharpen than simpler carbon steels. Proper abrasives and sharpening techniques are required.

Powdered Metallurgy Steel

Crucible CPM M4: Hardness of 63-65 HRC. High-wear resistance, edge retention, and toughness, but more difficult to sharpen.

Composition:

- 1.4% Carbon

- 4% Chromium

- 5.25% Molybdenum

- 4% Vanadium

- Other minor alloying elements

The hardness of the steel is measured on the Rockwell Hardness Scale (HRC), with higher numbers indicating greater hardness. Generally, steels with higher hardness (above 60 HRC) have better edge retention but may be more brittle and difficult to sharpen. Softer steels (below 58 HRC) are tougher but may not hold an edge as well.

It’s worth noting that the performance of a knife also depends on other factors, such as the blade geometry, heat treatment, and manufacturing process, in addition to the steel composition.

Heat Treatment Process for Knife Making

Here is a basic heat treatment process for knife making:

- Annealing:

- Heat the steel blade blank to around 1500-1600°F (815-870°C)

- Hold at this temperature for 1-2 hours

- Allow to cool very slowly, such as being buried in ashes or vermiculite

This makes the steel soft and workable for grinding the blade shape.

- Stress Relieving (Optional):

- After grinding, heat the shaped blade to around 400-600°F (205-315°C)

- Hold for 1-2 hours

- Allow to air cool

This relieves internal stresses from the grinding process.

- Hardening (Austenitizing and Quenching):

- Reheat the blade to the austenitizing temperature, around 1450-1550°F (790-845°C)

- Hold at this temperature for 30 mins to 1 hour

- Transfer immediately to the quenching medium (water, oil, salt bath etc.)

- Quench until the blade is cold

This rapidly cools and hardens the steel to around 60-65 HRC.

- Tempering:

- Reheat the hardened blade to around 300-500°F (150-260°C)

- Hold at this temperature for 1-2 hours

- Allow to air cool

Tempering reduces brittleness while allowing the blade to retain good hardness.

This basic cycle of austenizing, quenching, and tempering is the core heat treat that hardens carbon/alloy steels and gives the knife blade its desirable hardness and strength properties.

Some makers may add additional steps like normalization or cryogenic treatment, but this annealing -> hardening -> tempering sequence is the essential foundation for properly heat-treating knife blades.

Western-style knives and Japanese-style Knives

Comparison between Western-style knives and Japanese-style knives, as well as full tang and partial tang constructions:

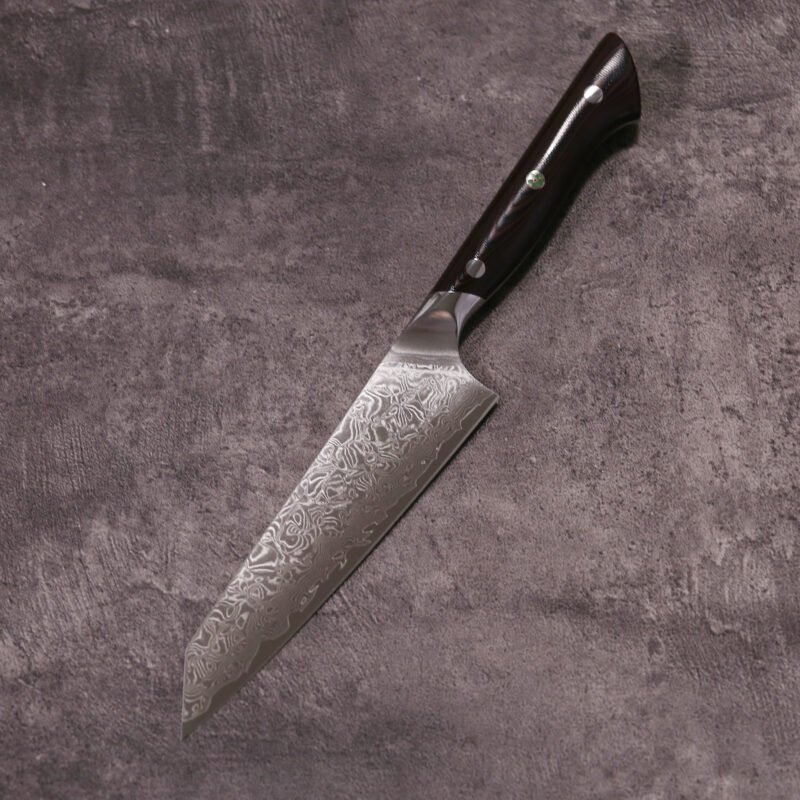

Western-style Knives:

- Typically features a full tang construction, where the blade’s metal extends all the way through the handle scales.

- Full tang provides superior strength, robustness, and balance.

- Heavier weight due to the full tang construction.

- Blade shapes often have a curved belly or clip point, designed for rocking/chopping motions.

- Handle designs vary, but many feature contoured shapes for a secure grip.

- Commonly made from high-carbon or stainless steels like 1095, 5160, AUS-8, VG-10, etc.

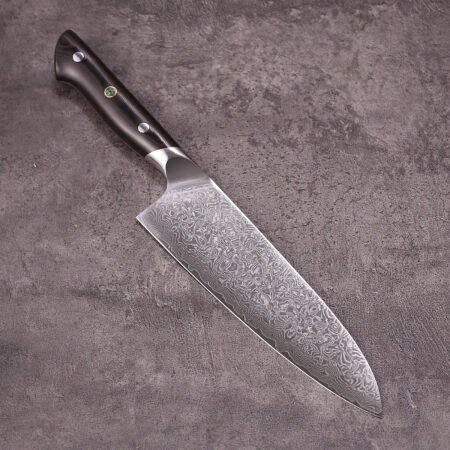

Japanese-style Knives:

- Traditionally features a partial tang (rat-tail or stick tang) construction, where only a portion of the blade extends into the handle.

- Partial tang reduces weight, making them more agile and nimble.

- Blade shapes are often straighter or have a subtle curve, designed for precise slicing and push/pull cutting.

- Handles are typically made of wood (like Ho wood or D-shaped) and have an octagonal or rounded shape.

- Commonly made from high-carbon or stainless steels like White Steel, Blue Steel, VG-10, etc.

Full Tang Construction:

- Provides superior strength, durability, and balance.

- Reduces the risk of blade/handle separation or tang breakage.

- Typically heavier weight due to the extended metal tang.

- More expensive to manufacture.

- Common in Western-style knives, hunting/survival knives, and some Japanese-style knives.

Partial Tang Construction:

- Lighter weight construction, more agile and nimble.

- Potential for tang breakage under extreme stress or impact.

- Handles may loosen over time if not properly secured.

- More cost-effective to manufacture.

- Common in traditional Japanese-style knives and some Western-style knives.

Western knives often prioritize strength and durability with full tang constructions, while Japanese knives emphasize precision and lightweight agility with partial tangs. However, there are exceptions on both sides, and the choice ultimately depends on the intended use and personal preferences of the user or manufacturer.

Which Knife Style is Better?

While both Western and Japanese-style knives have their own unique strengths, the choice ultimately comes down to personal preferences and intended usage. Western-style knives, with their full tang construction and robust designs, offer superior durability, strength, and balanced weight distribution. Japanese-style knives, on the other hand, prioritize precision, agility, and lightweight construction, making them better suited for delicate slicing tasks.

Personally, I prefer Western-style kitchen knives because they are more balanced, durable, and don’t demand as much from the user as Japanese ones. For the average household, a good quality Western-style chef’s knife, a paring knife, and perhaps a serrated bread knife should suffice for most cooking needs. The average family doesn’t need to buy both Japanese and Western-style knife sets, as that would cost a significant amount of money and is generally not necessary.

A well-made Western-style knife, with proper care and maintenance, can serve as a versatile and long-lasting workhorse in the kitchen, capable of handling a wide range of cutting tasks without requiring the same level of technique and skill as traditional Japanese knives. Unless one is a professional chef or has a specific preference for Japanese knives, investing in a high-quality Western-style knife set should provide a practical and cost-effective solution for most home cooking needs.

Characteristics of a Good Knife

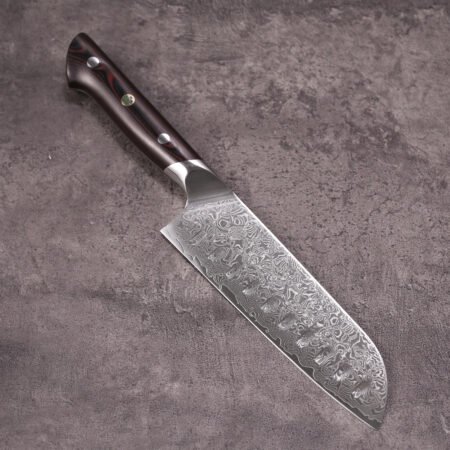

My Suggestion: Good Steel + Full Tang (with stainless steel bolster) + Classic Design

A high-quality, well-designed knife should ideally have the following key attributes:

- Good Steel:

The blade should be made from high-quality steel that offers a good balance of edge retention, toughness, and corrosion resistance. Popular options include high-carbon stainless steels like VG-10, AUS-8, 154CM, as well as powder metallurgy “super steels” like CPM S30V, S35VN, etc. The steel composition and heat treatment play a crucial role in the blade’s performance. - Full Tang Construction:

A full tang, where the blade’s metal extends all the way through the handle, provides superior strength, robustness, and better weight balance compared to partial tangs. This reduces the risk of blade/handle separation or breakage under heavy use. - Stainless Steel Bolster:

As you mentioned, a stainless steel bolster (the thick portion between blade and handle) offers excellent corrosion resistance, durability, added weight/balance, finger protection, and prevents cutting board gouging. It’s a desirable feature in a quality kitchen knife. - Classic Design:

A well-designed knife should have an ergonomic, time-tested handle shape that provides a secure and comfortable grip. The blade shape should be versatile and suited to common kitchen tasks like slicing, chopping, and dicing. Classic Western designs like the chef’s knife, paring knife, and utility knife have proven their worth over decades of use.

By combining high-performance steel, a robust full tang construction, a durable stainless bolster, and a classic, ergonomic design, you get a knife that is not only sharp and long-lasting but also well-balanced, comfortable to use, and built to withstand the rigors of daily kitchen work for years to come.

Good kitchen knives may cost more upfront, but their quality construction and materials make them a worthwhile investment for serious home cooks or professionals who demand the best tools for their culinary pursuits.